INDUSTRIAL RESEARCH OBJECTIVES

This part of the project focuses on defining the factory as a machine, a system in which the important components can be described as models that represent resources over time, in the Lean way.

We will identify the requirements for the three models that represent the Smart factory:

- Lean Accounting, which variables and relations represent the economic model of the company that owns the factory

- Lean Manufacturing, which variables and relations represent the way of producing

- Cost Engineering, which variables represent the product cost.

EXPERIMENTAL DEVELOPMENT OBJECTIVES

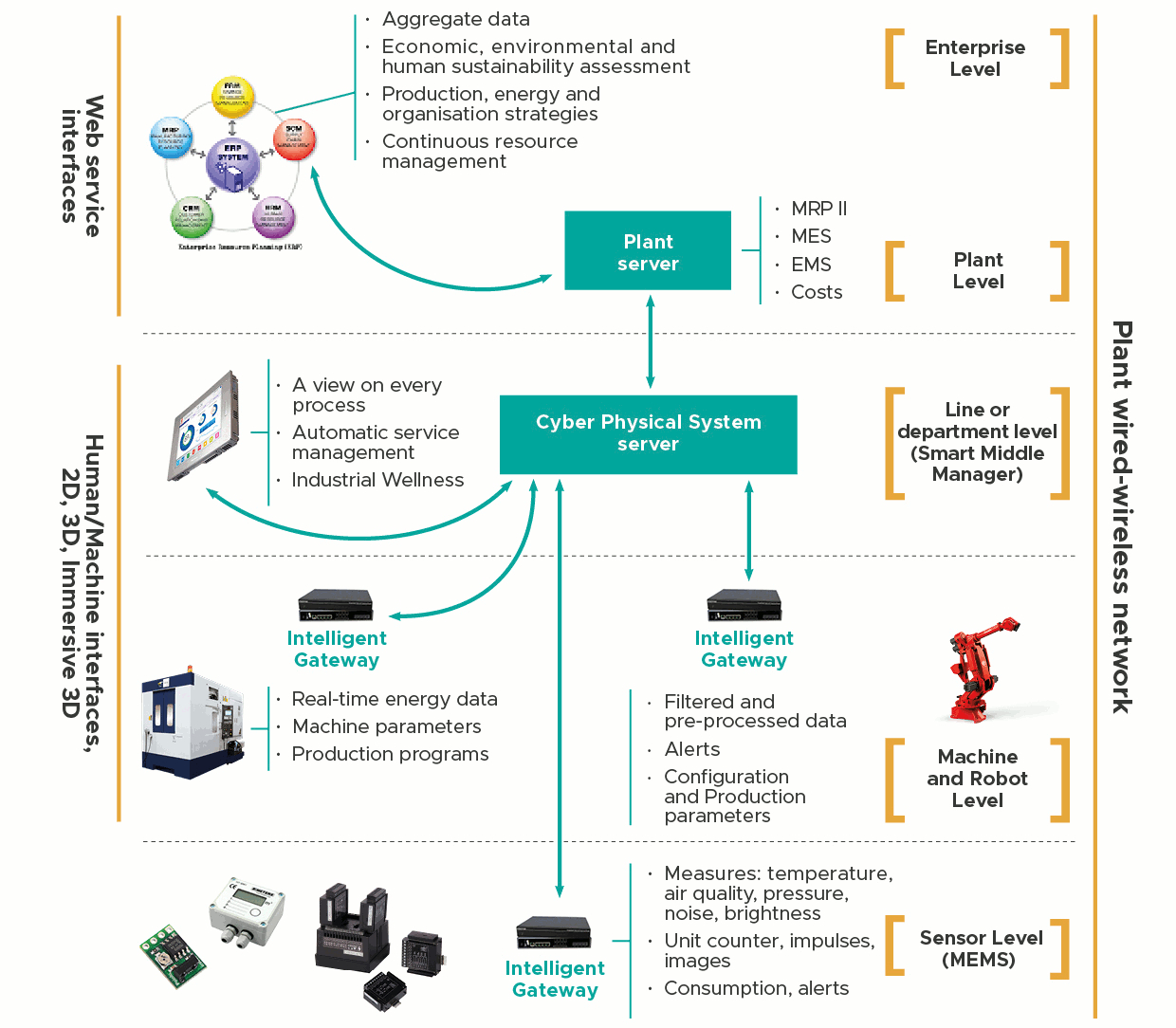

The experimental development aims at making the whole factory a big measuring machine, by developing the following prototype infrastructure:

- Edge Computing network nodes and intelligent gateways

- Cyber Physical System composed of:

- measuring machine

- modelling machine

- reasoning and running machine

- universal interface machine.

END USERS

The prototypes will be applied in industrial end users representing the real world.

ELBI International Spa (Coordinator): |

|

|---|---|

| 1 End User | Machine and robot network security |

| 1 End User | Technical Production Communication |

| 1 End User | Environmental context |

| 1 End User | Wellness |

Agrindustria Tecco Srl |

|

|---|---|

| 1 End User | Manufacturing with intelligent energy demand |

Fidia SpA |

|

|---|---|

| 1 End User | Manufacturing with predictive maintenance and augmented reality |

Galeasso Srl |

|

|---|---|

| 1 End User | Automatic and robotized manufacturing |

Nanchino Automazioni Industriali Srl |

|

|---|---|

| 1 End User | Conscious manufacturing |

Eurodies Srl |

|

|---|---|

| 1 End User | Manufacturing Knowledge Base |

Sistemi Sospensioni SpA |

|

|---|---|

| 1 End User | Manufacturing with real-time production costs control |

Tecnikabel SpA |

|

|---|---|

| 1 End User | Manufacturing with intelligent energy demand |

CVA Trading Srl |

|

|---|---|

| 1 End User | Manufacturing with intelligent energy demand |

The social part of the transformation: THE SMART MIDDLE MANAGER

The HOME project wants to make available to the people working in the plant, the information necessary to manage the processes in real-time.

This human function that manages the factory becomes Smart if supported by the adequate analysis, supporting and alerting tools.

The Cyber Physical System will be the central system to support factory management, since it will provide:

-

real-time support for decision making

-

interfaces for machines, robots and applications

-

complete automation for the factory subsystems that do not require human intervention (e.g. Energy, Climate, Sub-services).

The idea of tackling the factory as a big measuring machine, is an approach that comes back cyclically, because it fills the need for an overview of every correlated phenomenon: economic, productive, social and organisational.